Watch Now

Engine Summary

Collapsible content

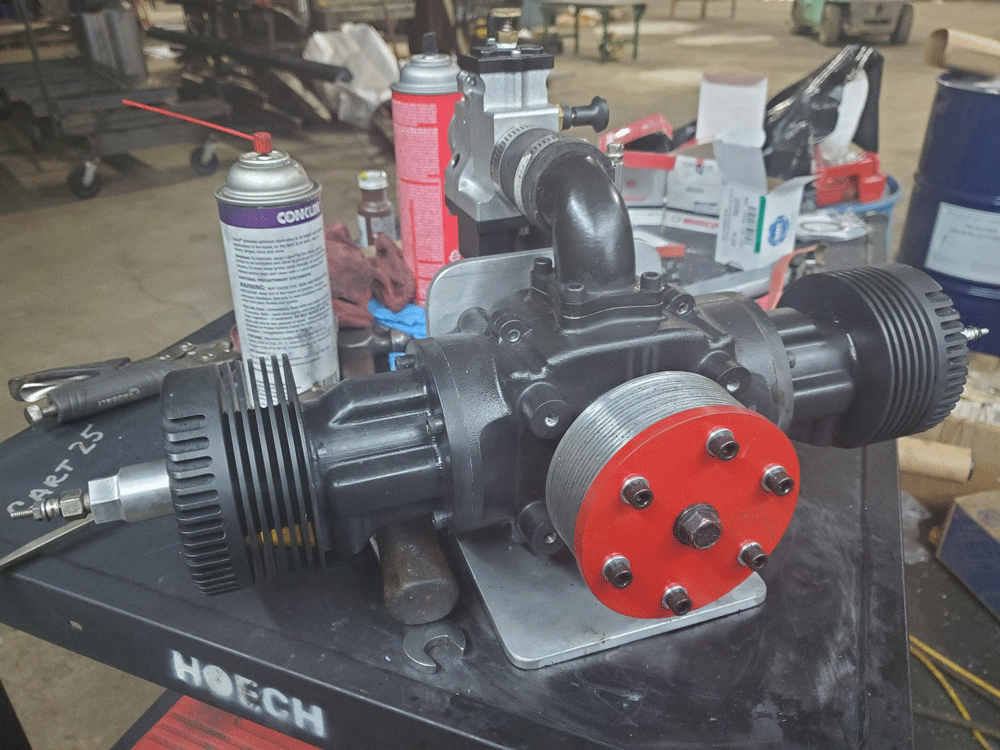

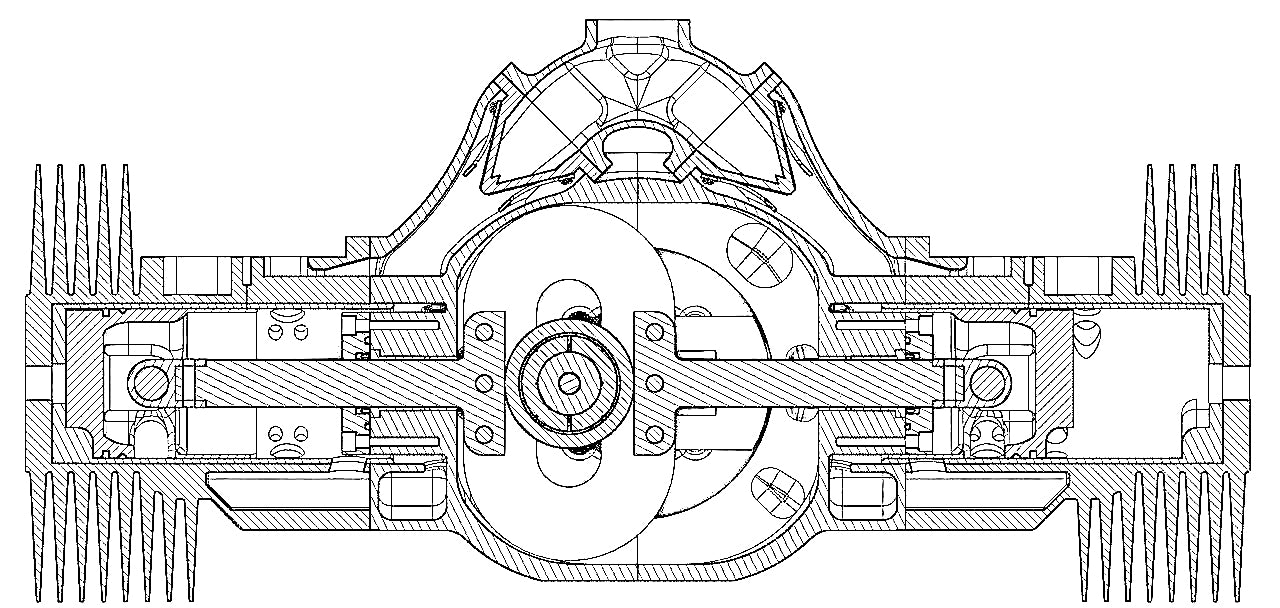

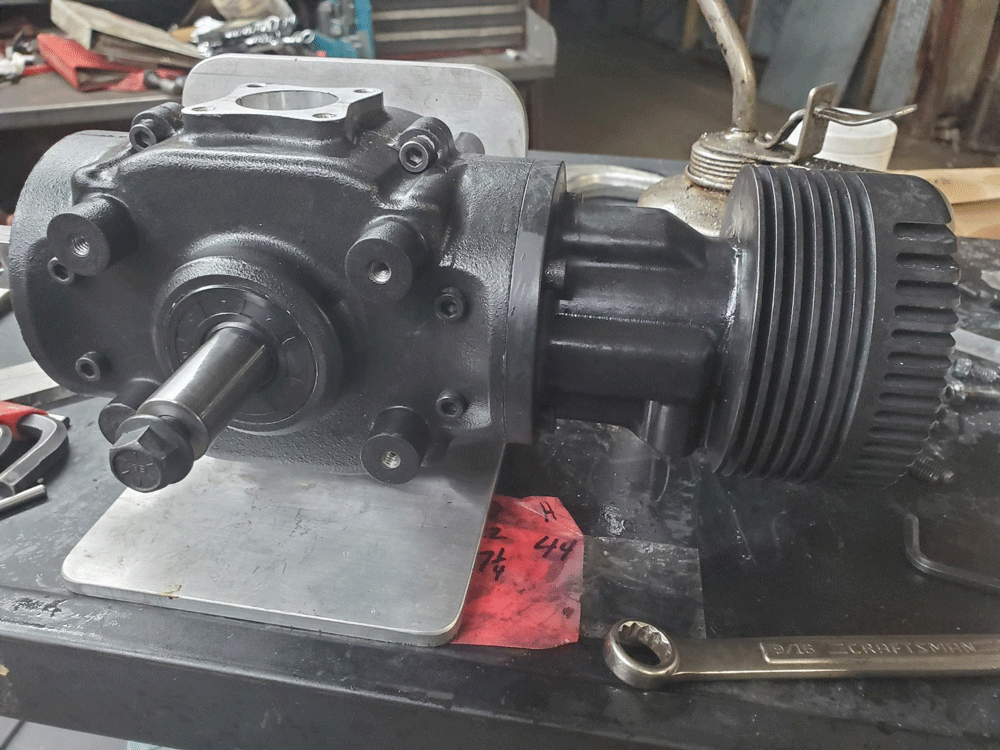

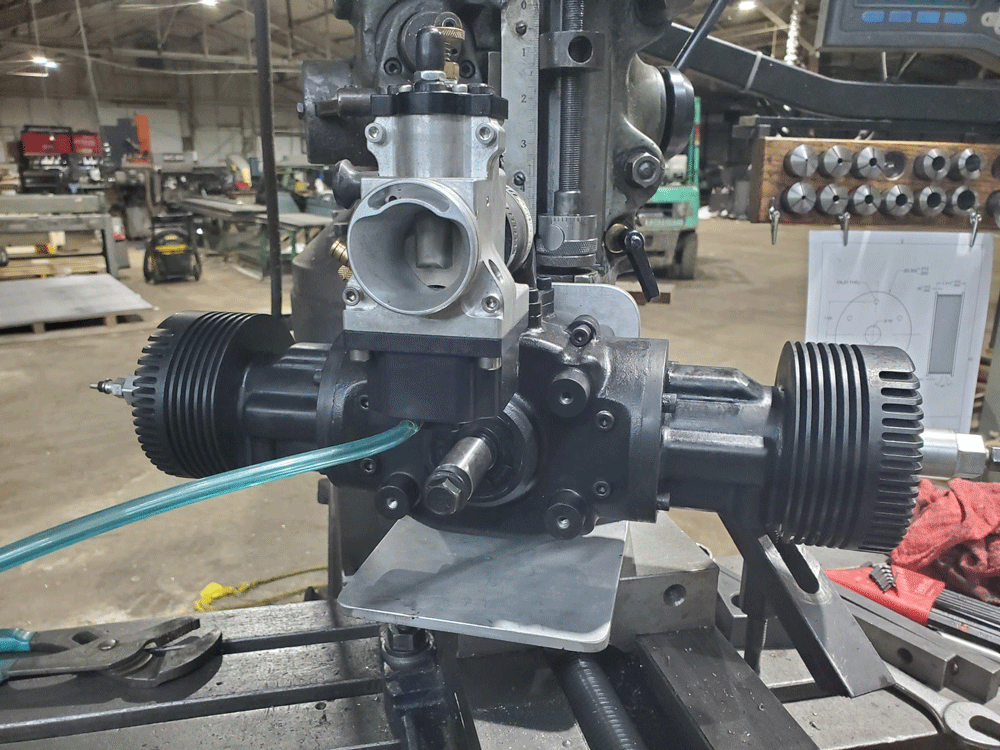

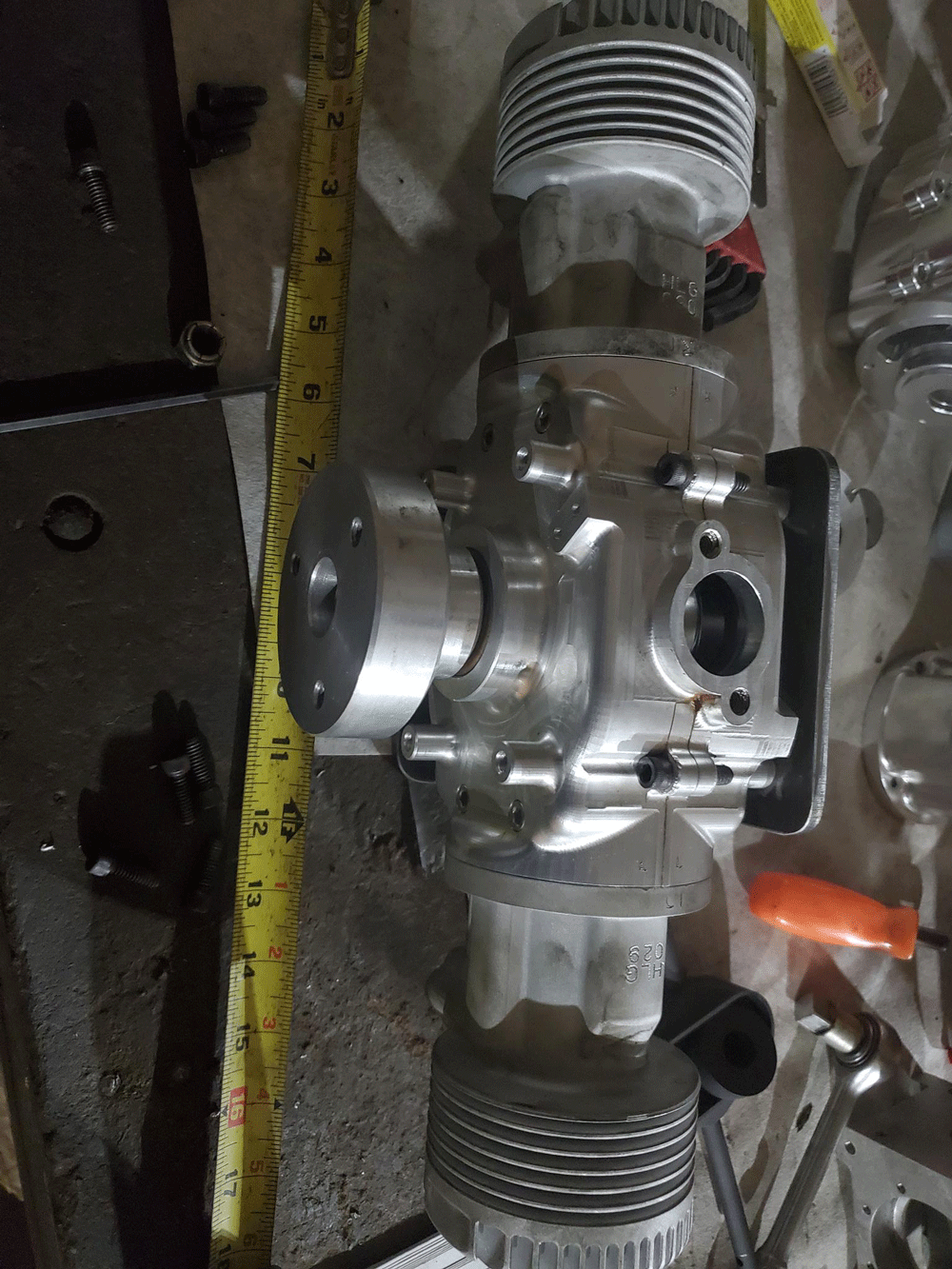

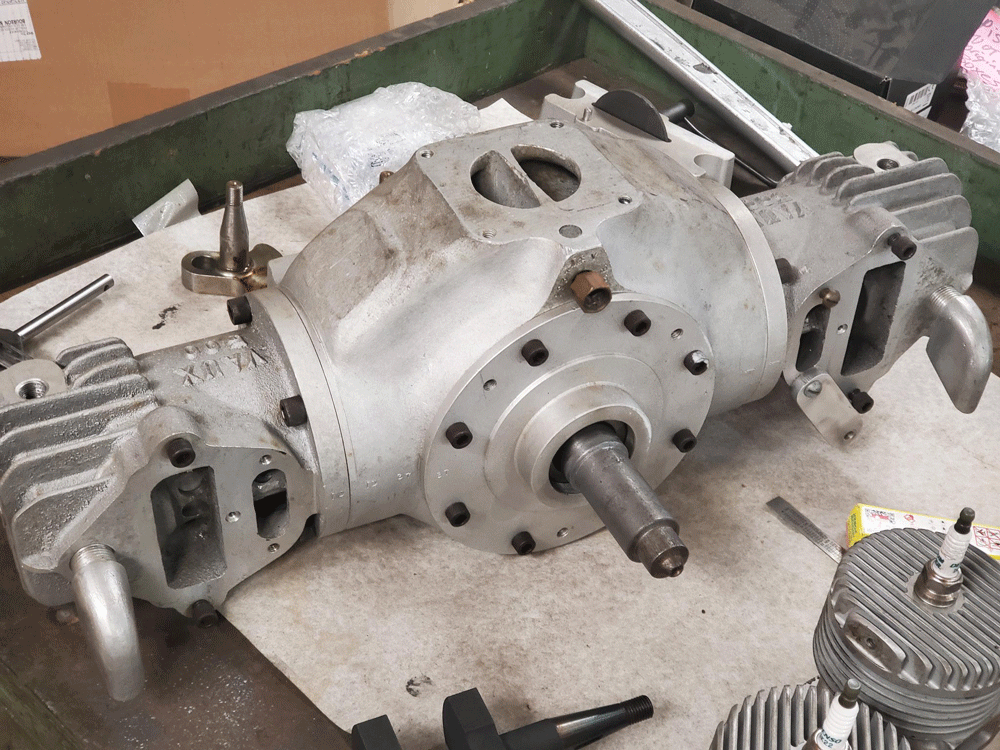

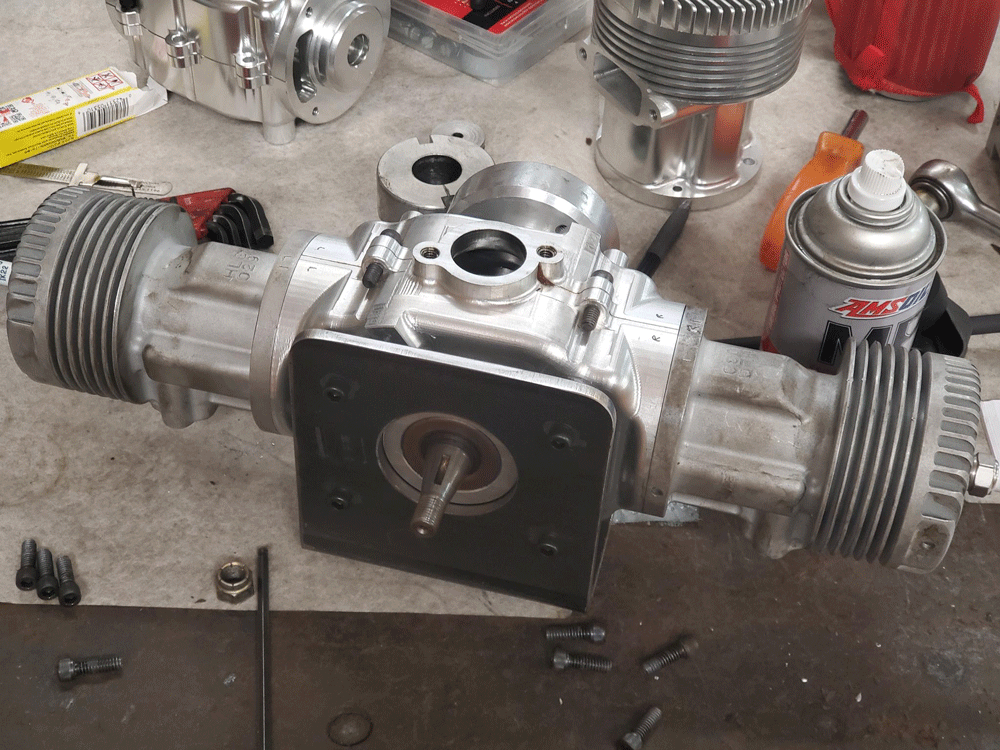

Technology #1, Fickett-Jacobs Cycle Ultra-Boxer Engine

The goal of this first technology is to decentralize dozenal kilowatt class utility grade power in a package that is small, lightweight, reliable, long lasting, efficient, maintenance friendly, and inexpensive. This will allow for many industrial, construction, and commercial processes that currently aren’t economical to become economically viable. A specific example is land development, without need for grid tie millions of acres of land are suddenly available for economic development. Developing nations will make prolific use of this technology.

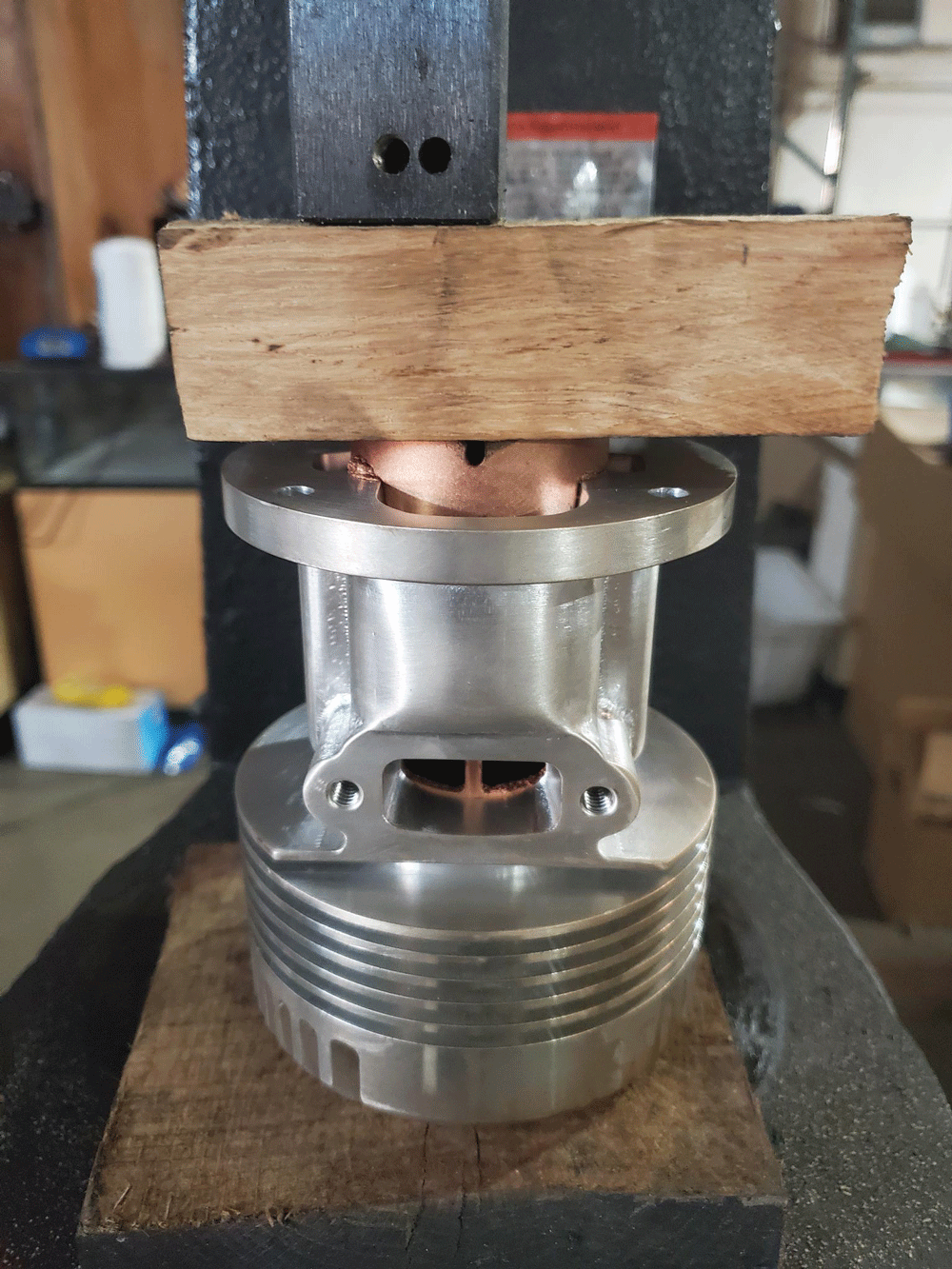

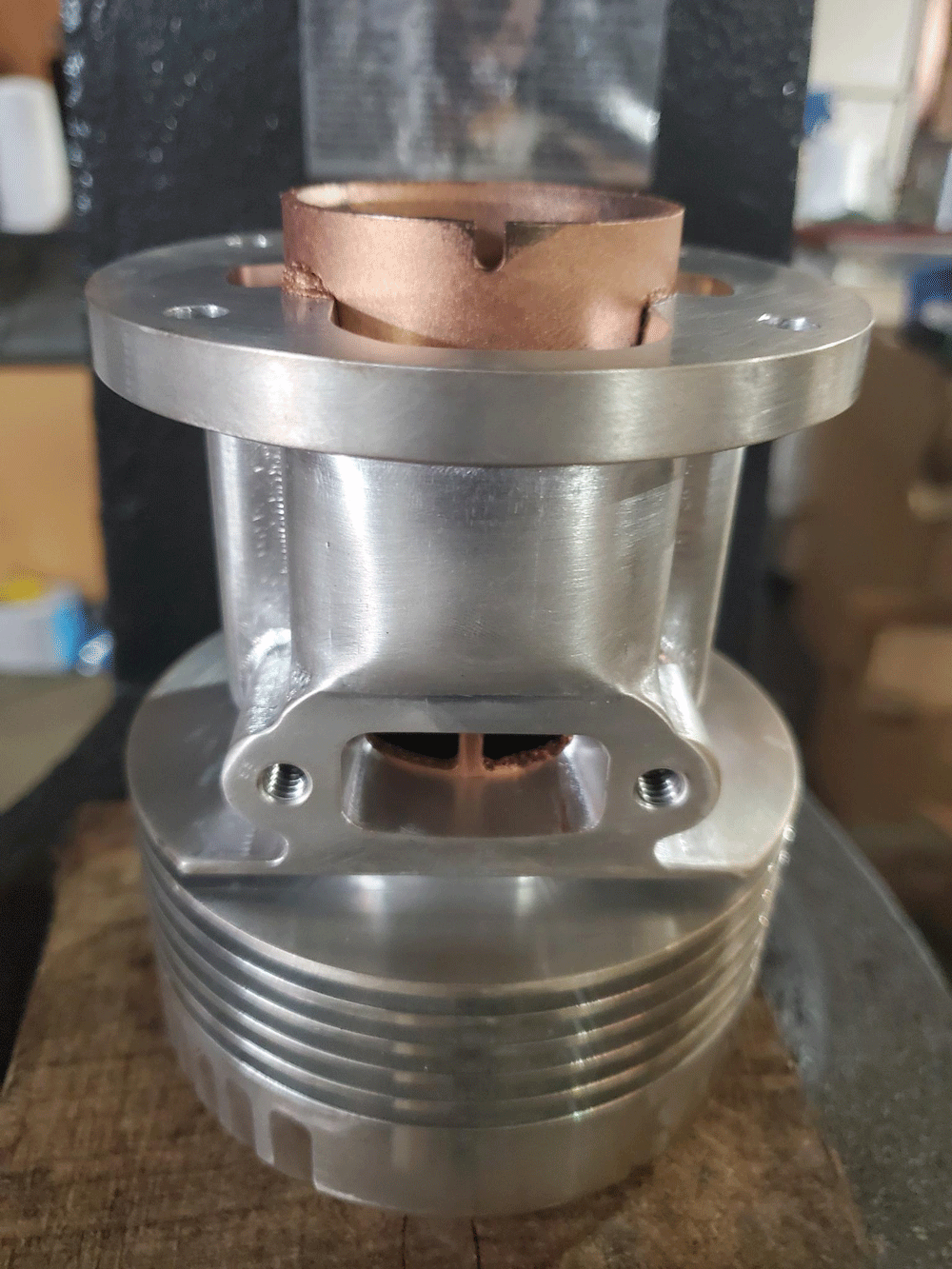

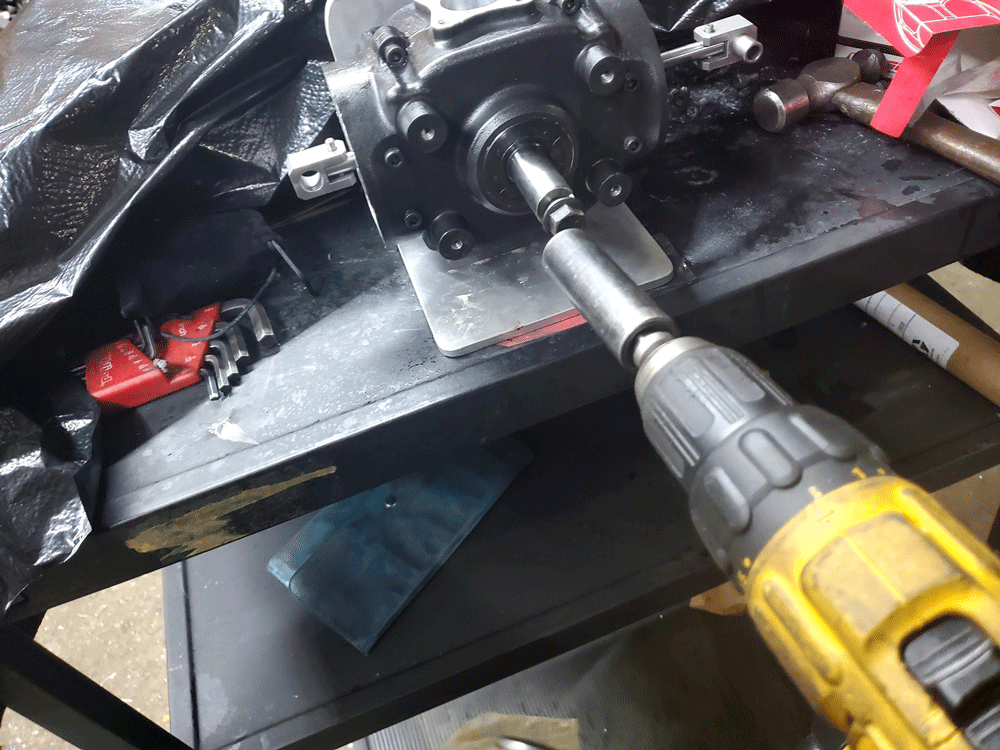

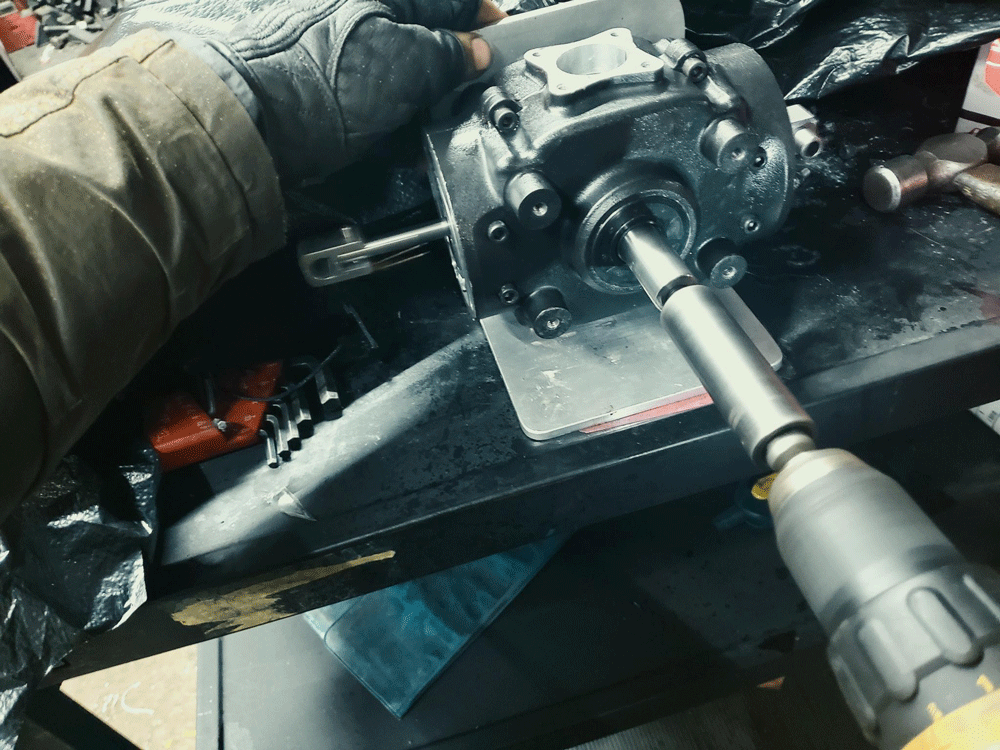

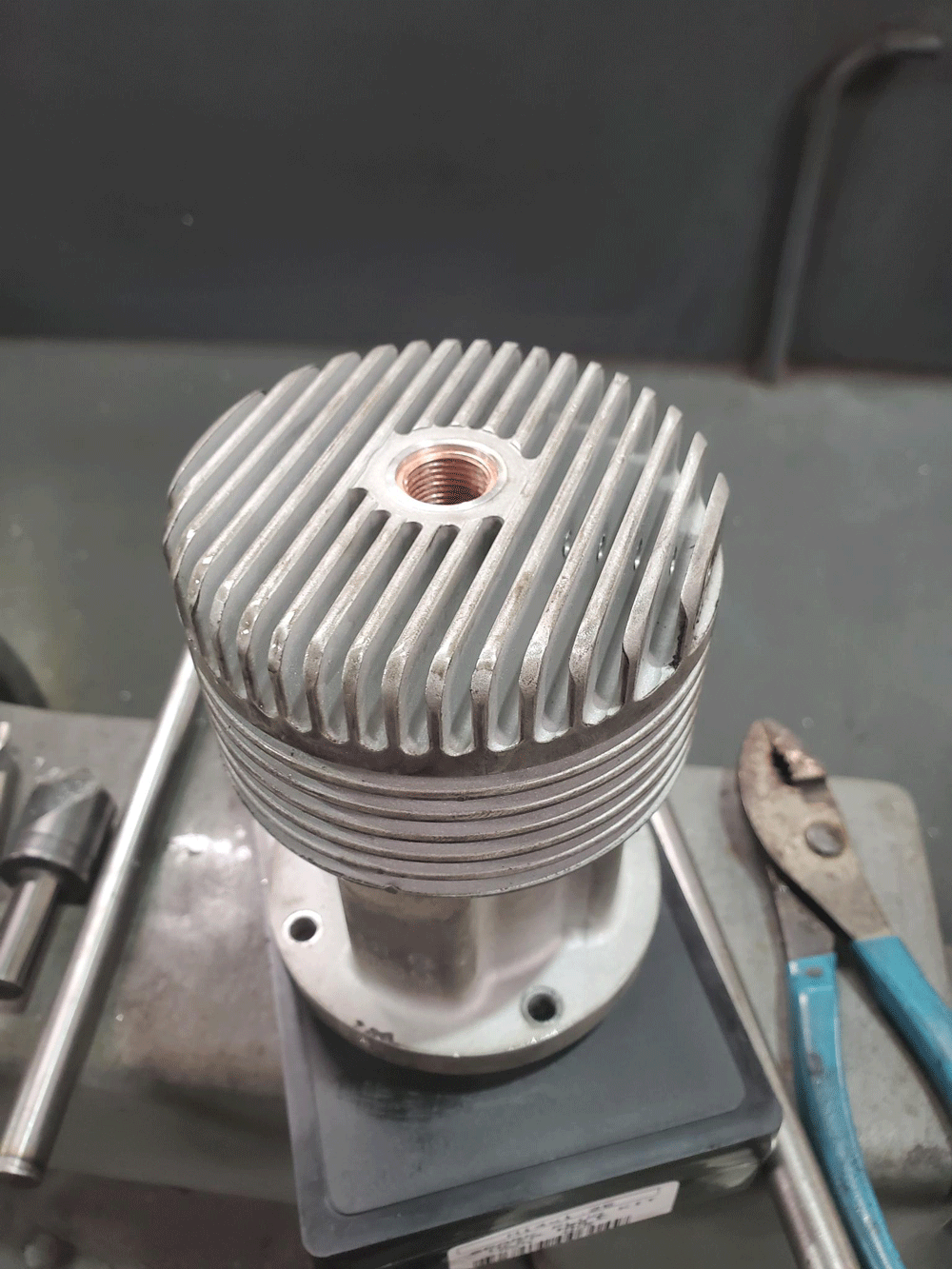

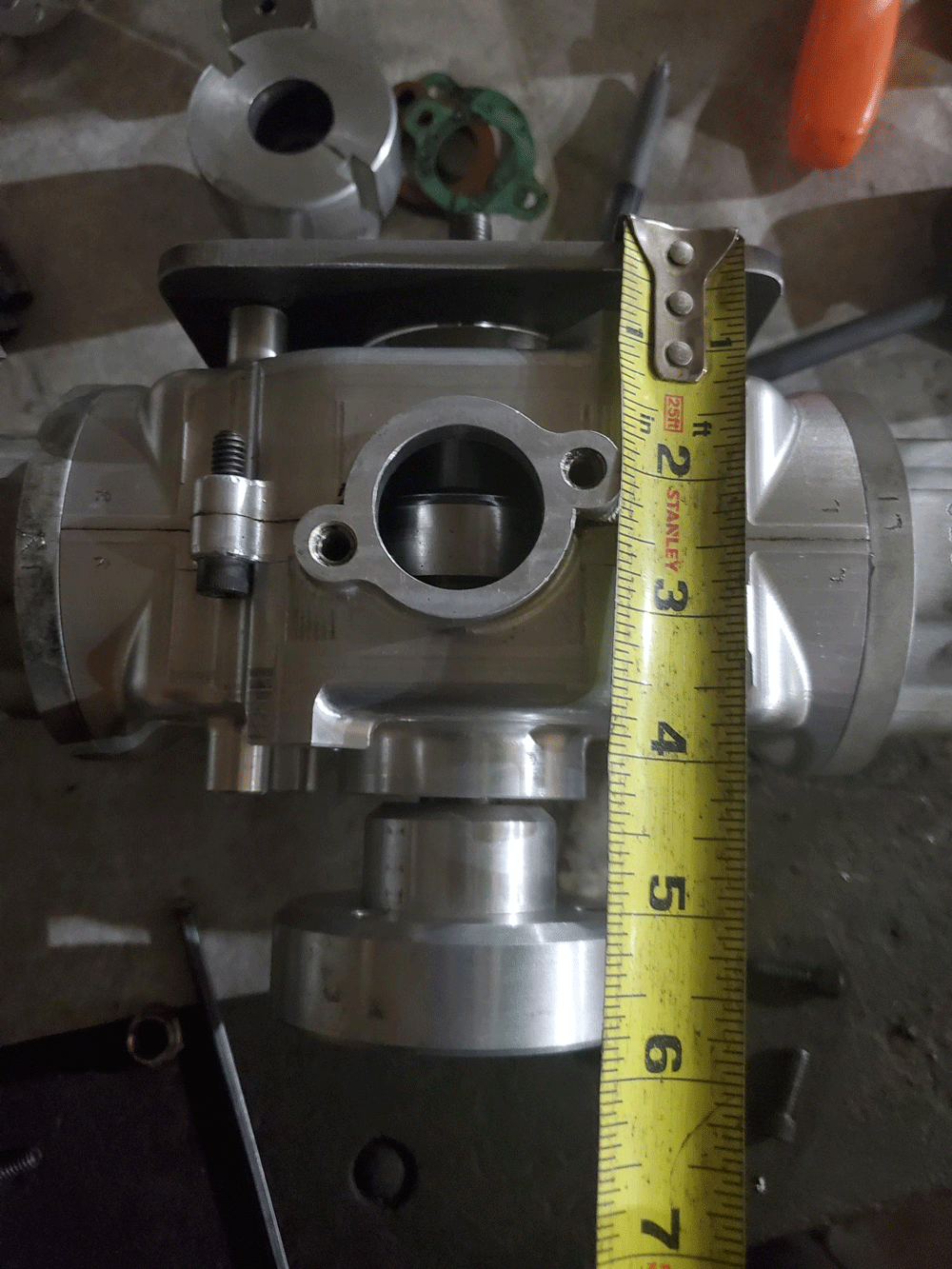

- Mechanically simple, only two moving parts. Can be fully rebuilt in under 15 minutes with less than 4 tools, can be top overhauled in less 5 minutes with 1 tool.

- Designed from the ground up for fully automated manufacturing.

- Thermal efficiency of over 50% naturally aspirated, making it cost competitive to grid.

- High thermal efficiency means EGT’s are below 220 F. Thermal signature 8X lower than conventional engines (Stefan–Boltzmann law). 80% of USAF aircraft combat losses since 1960 due to heat signature! (Titterton 2006)

- Over 4 horsepower per pound without using exotic materials. This is comparable to a Formula 1 engine.

- Engine is not affected by G-force and can be mounted in any orientation irrespective of gravity which is important for aviation applications.

- Highly modular design facilitates multiple displacements and mission profiles using one integrated, economized, and scaled production engine. Topologies and displacements ranging from a 125cc flat 2 to a 1400cc flat 16, with power outputs ranging from 18 horsepower to 160 horsepower and in-between are available with one design. A second larger ultra-boxer engine whose baseline displacement begins at 500cc and can be modularly increased to 4 liters is planned for the future.

- Multi-fuel capabilities ranging from natural gas, methane, propane to diesel, and every hydrocarbon in-between (gasoline, jp-8, jet-A, kerosene, naphtha, etc) including ethanol, watermeth, otto-fuel 2, and so on without adjustment or re-tuning.

- Ability to use low octane fuels without detriments to performance

- Splash lubricated crankcase is isolated from combustion, the crankcase oil will last upwards of ten thousand percent longer than conventional engines oil.

- Low emissions profiles can meet many environmental standards without catalytic converters.

- Perfectly balanced design with no secondary imbalances.

- Catalytically assisted compression ignition system gives our engine a 2 factor exemption to CARB’s ban on small engines, giving us a de-facto monopoly (via CARB regulations) on the North American small engine market.

- Pure chemical and mechanical operation makes the engine impervious to EMP attacks.

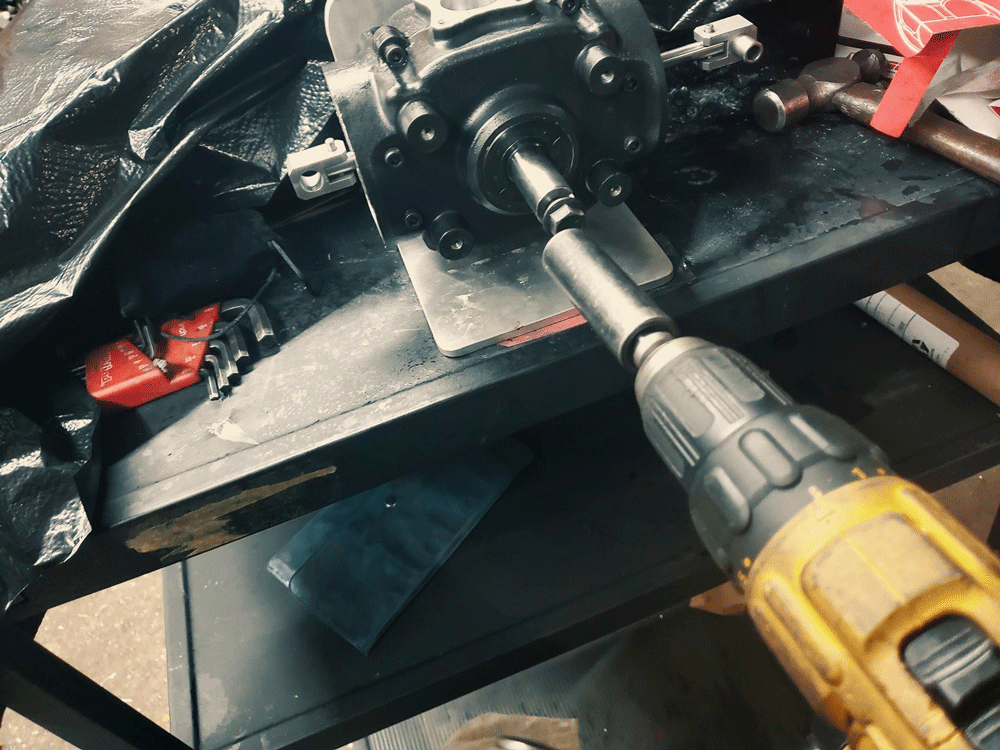

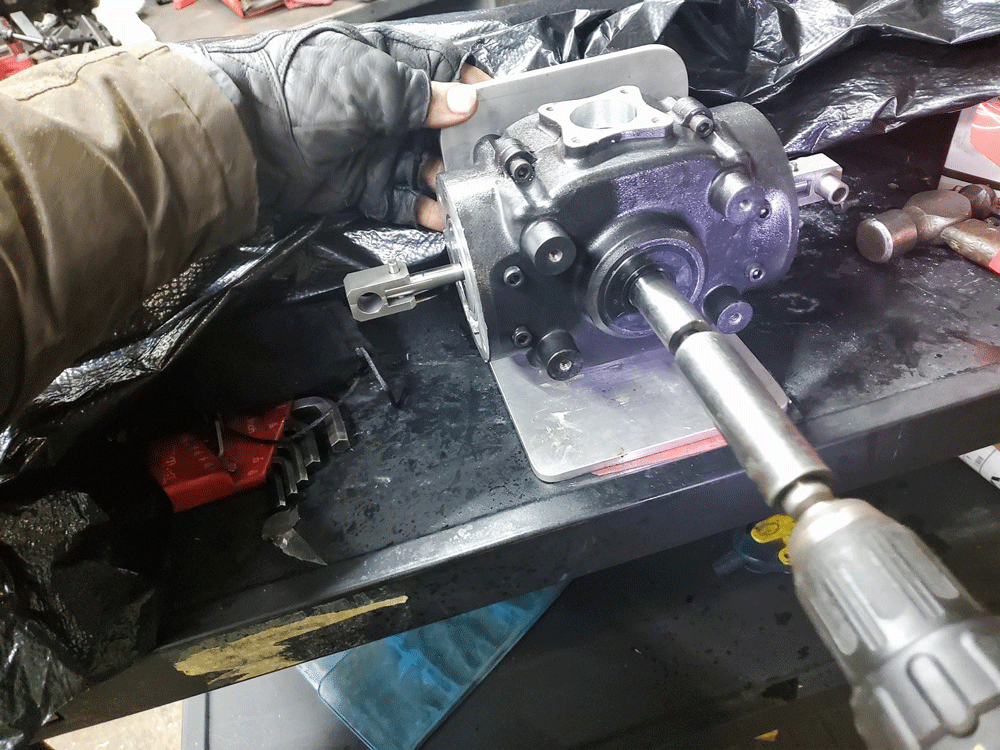

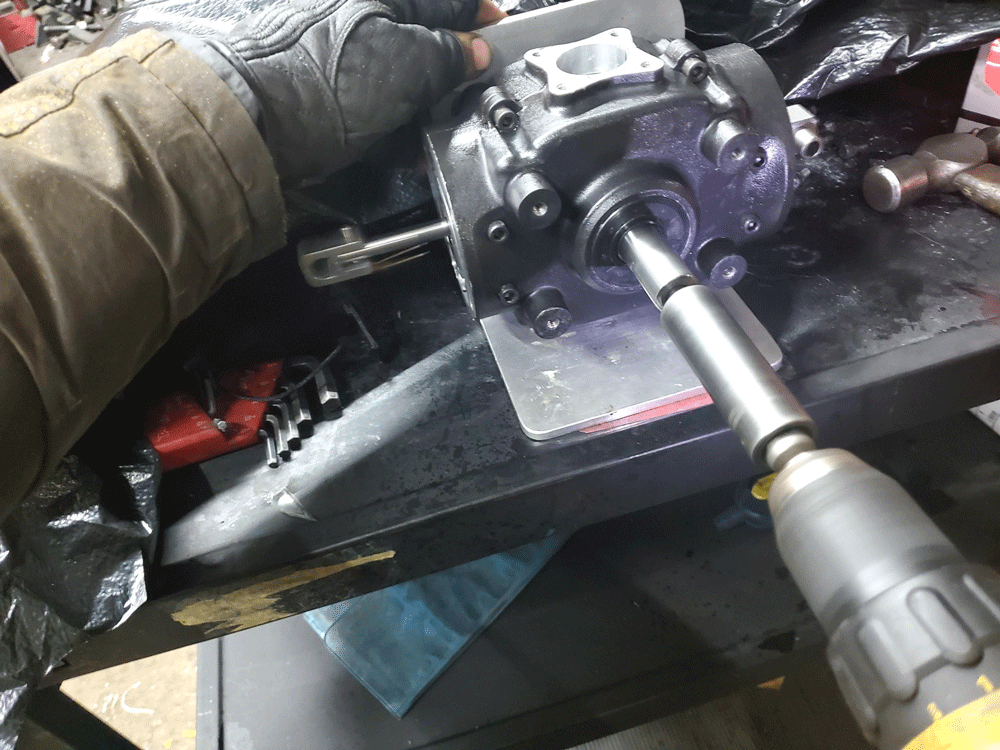

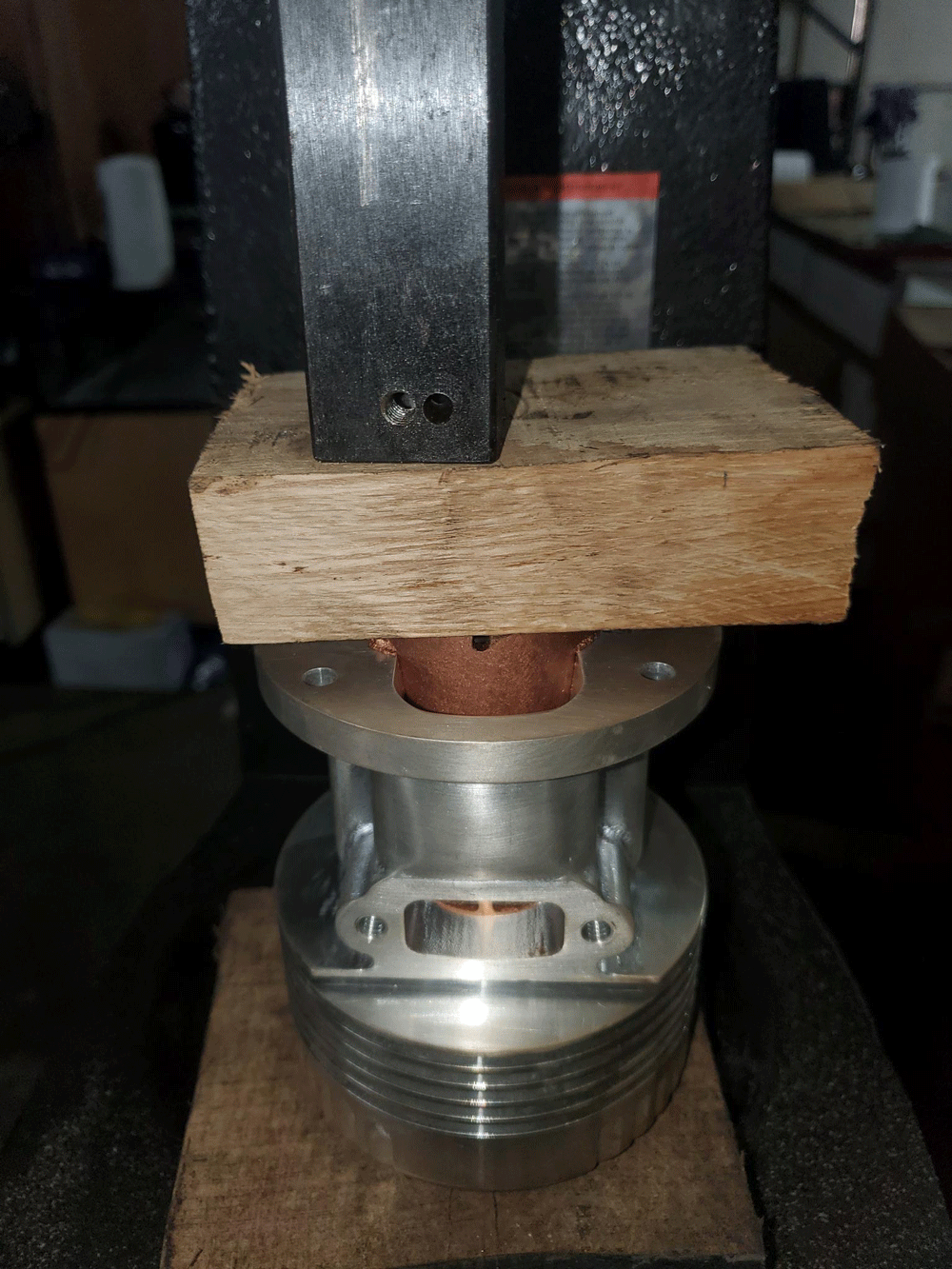

We have multiple fully functioning prototypes of several different sizes that perform as we claim.No other competitor in this market can say the same.

Technology #2, Caducean Pump

This special pump can be coupled to any engine and convert it into a true fuel agnostic engine. This pump functions by endonically phase changing any combustible fluid (liquid or gas) into a supercritical fluid. When coupled to any engine (including but not limited to our own internally developed engines) it allows the engine to run, without adjustment or re-tuning, on any flammable or combustible fluid. Examples include

- gasoline

- kerosene

- jet fuels

- diesel

- propane

- bunker oil

- unrefined waste vegetable oil

- waste motor oils and automotive fluids such as waste transmission fluid, gear oil, and even coolant

- depolymerized tires and plastics of any type (except chlorine containing plastics)

- toxic waste chemicals such as Technology #2, Caducean Pump

- h as solvents and liquified medical and pharmaceutical waste

- watermeth as diluted as 20 percent, meaning alcohol fuels requiring no distillation IE straight from fermentation are viable.

- unrefined crude oil

- coal-water-slurry fuels

- and much more.

- This cuts the grid out as a middle man entirely, and allows consumers to purchase their energy directly from the drillers, miners, and processors whilst also being fully backwards compatible with all legacy fuels and fuel distribution infrastructure. This is true even if the fuels are mixed or heavily contaminated with water.

- Octane and cetane ratings are obsoleted by this technology.

- The pump takes these materials and chemically breaks them down into their baseline elements and chemical, which is hydrogen and carbon monoxide, meaning the engine only ever sees a consistent and clean fuel regardless of what goes into the tank.

- Think of it like a miniature oil refinery under your hood, but a refinery that is not energy intensive.

- Oil refineries strive to produce medium weight hydrocarbons such as diesel and gasoline.

- Because this pump is optimized to produce simple, lightweight gases such as methane and hydrogen, the energy and complexity is eliminated and thus only a single stage device (the pump) is required.

- This greatly increases energy efficiency by allowing us to use the carbon content of fuels, even coal, as a chemical re-agent (which is a pseudo catalyst) to produce hydrogen from water in such a way that more net-energy is obtained than lost in the reaction (unlike electrolysis).

- This may seem to violate the laws of thermodynamics at first, but it doesnt in this case because the carbons presence greatly reduces the energy required to break the covalent bond between hydrogen and oxygen. In other words, we’re not using water as a fuel, but rather an oxidizer, to “burn” the carbon, and release the higher-value and higher energy hydrogen. This is why there is a net increase in total energy output which effectively more than doubles the de-facto energy density of carbon based fuels.

Technology #3, Prototype X, Its Both a Rotary AND Piston Engine

This extremely novel engine posses’ all the advantages of the ultra-boxer, but works very differently. It is a hybridized fickett-jacobs-cheng cycle. The pistons spin as they reciprocate simultaneously.

- Power to weight ratio of over ten horsepower per pound, on par with the lightest electric motors in the world.

- This 5 liter displacement engine is 1 foot in diameter and two feet long, nominally.

- The engine is made almost entirely from composites and weighs less than 300 pounds, yet is capable of over 5 thousand horsepower.

- Perfect balance at all RPM’s. No secondary or primary imbalances at all.

- Internal gas temperatures never exceed 500 F. eliminating oxides of nitrogen emissions.

- Almost all components never leave the hydrodyanic film regime of the stribeck curve, so the parts will never wear out. Conservative projected lifespan of over 10 million miles in commercial trucking service.

- Maximum volume to surface area ratio possible.

- Can be entirely rebuilt in 5 minutes without removing the engine from the bay.

- Strong potential to use nuclear fuels for space applications that need megawatts of power on-tap.

- Thermal efficiency of over 85% means it’s considerably cheaper for one to produce their own power than buy from the grid. Over 95% if one uses combined heat and power. This completely decentralizes megawatt class utility scale power in a package that is small enough to comfortably fit under the hood of a pickup truck. Industrial processes that are currently not viable will become so overnight. Decentralized high quality manufacturing and material manipulation will become ubiquitous. High energy experiments will become available to the masses. Decentralized metal and glass recycling.

- Incredibly simple design, only 3 moving parts.

- Very low cost of manufacturing. Exceptionally conducive to fully automated, lights out manufacturing.

- Higher volumetric efficiency than any conventional engine.

- Military applications are too long to list. Please call for details.

- Direct supercritical water injection eliminate emissions without the need for EGR or catalytic converters to even the strictest standards.

Want to Learn More?

Contact us to schedule a consultation with Sky to build your custom engine today!